New LIGHTWEIGHT MARBLE concept

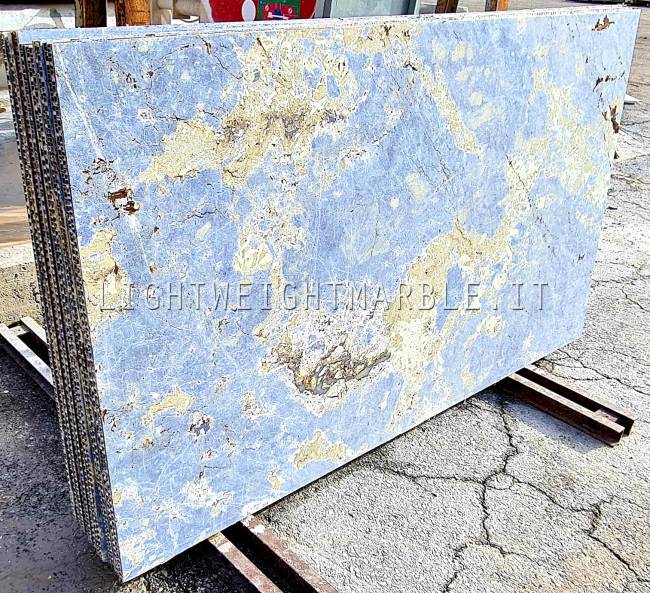

Let’s start with the traditional stone slab obtained by sawing an entire block of stone using a frame, cut into "slices" or slabs with the minimum standard commercial thickness of 2 cm.

The dimensions of the stone blocks depend on the chemical-physical characteristics of the stone itself and the geomorphological characteristics of its quarry.

With compact and hard granite, such as Black African granite, you can make large blocks to obtain large slabs, for example, of 320-340 x 180-200 x 2 cm.

With uneven and naturally fractured marble, such as Giallo Siena marble, small blocks are made to obtain small slabs, for example, of 180-200 x 100-120 x 2 cm.

The nominal specific weight of the stone is 2700 kg/ m3, so a 2 cm thick stone slab weighs 54 kg/m2.

Considering the size and weight of the stone slabs, it is clearly necessary to obtain sub-measurements from the slabs that are within human capacity for the relative installation of walls and floors in the construction sector; however, the weight of sub-measurements with a 2 cm thickness is still heavy for covering and flooring in the nautical field.

You should also consider that, for the same stone, the larger the slab, the greater its fragility in case of impact and stress, (just think about use in exterior façades in the event of hurricanes or earthquakes), and the relative anchorage structure must have suitable bearing characteristics to meet the imposing loads of the stone. This is why we need to transform weight and fragility (which since the dawn of time have limited, if not eluded, the use of large sized stone for façade coverings) into lightness and tenacity, maintaining the natural aesthetic appearance of the stone to touch and see.

Lighweight granite - Producied by FFPANELS®

Thus, LIGHTWEIGHT MARBLE FFPANELS® were designed with increasingly performing solutions, derived from new construction concepts that characterise and define it as any flat or curved stone slab with standard thicknesses of 5 and 10 mm, stratified and laminated on an aluminium honeycomb support by means of a fibreglass cloth impregnated with bi-component epoxy adhesive; these layers and laminations, carried out according to exclusive production standards, with specific raw materials (selected aluminium honeycomb structures, selected fibreglass cloths and exclusive bi-component epoxy adhesives), give the stone slabs optimal physical characteristics such as: lightness, toughness, high strength against mechanical stress, and, consequently, the search for targeted production peculiarities: absolute durability.