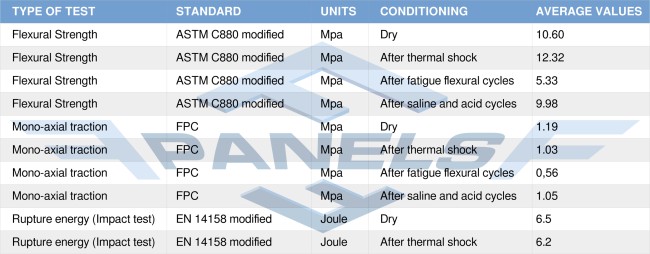

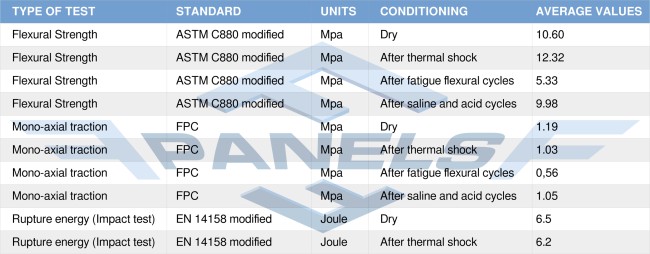

FFPANELS® lightweight panels are constantly monitored via quality control analysis.

An example follows in the table below of quality control carried out at the end of the production cycle on a batch of FABYCOMB® lightweight marble panels in GALIZIA ZARCI: